Production processes :

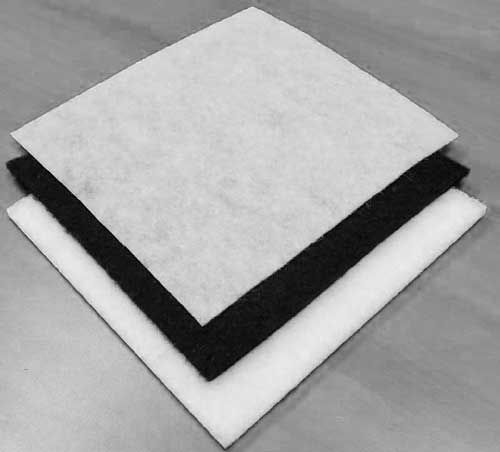

- Airlay forming

- Carding and lapping

- Needle Punch

- Thermo-bonding

- Nonwoven finishing

- Nonwoven converting

- Textiles recycling

- Garnetted

Fibers :

- Natural

- Synthetic

- Recycled

- Blends

Weight :

70g/m² to 5000 g/m²

Thickness :

6 mm to 175 mm

Deniers :

2D – 200D

Research & Development philosophy

Quality &

Competitive prices

Machines for recycling

High production equipments to fiberise and blend many types of textiles waste, scraps, bi-products into usable fibers for nonwoven industries. Many types of materials can be recovered from the environment and recycled into high quality insulation materials. They include polyester, nylon, acrylic, wool, cotton and many other post-industrial materials.

Dedicated to quality, recycling and the environment